Extrusion

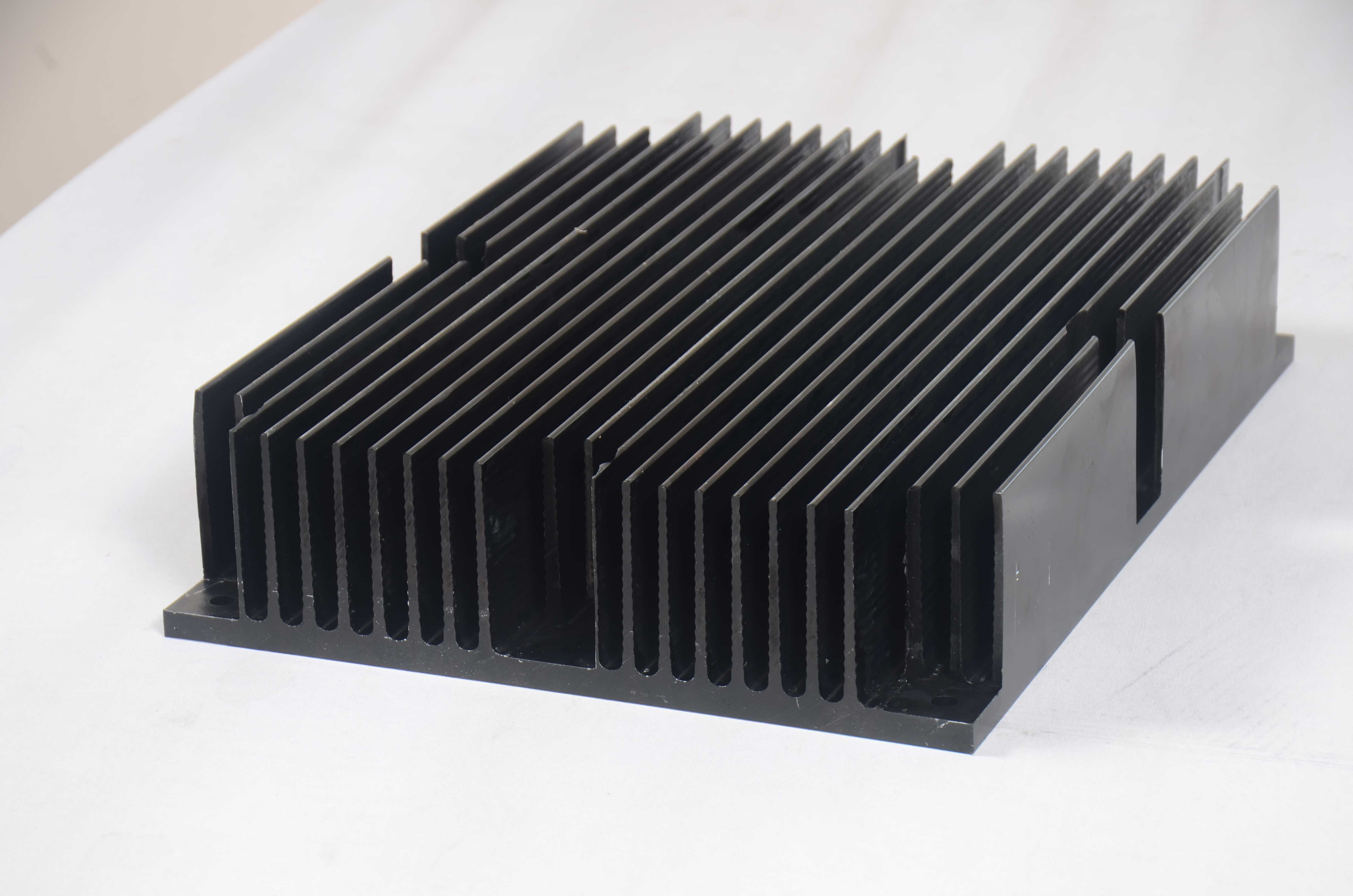

An extrusion heat sink is a type of heat sink that is manufactured using an extrusion process. This process involves forcing hot aluminum billets through a steel die, shaping the aluminum into a long, continuous profile with a specific cross-section. This profile design maximizes the surface area of the heat sink, which is key to its function.

Leveraging over 30 years of experience, Akash Heat Sink offers a vast selection of more than 100 die profiles. This extensive library ensures we have the perfect solution to meet your specific heat sink requirements.

Skived fin heat sinks are a powerful solution for efficient heat dissipation in air-cooled environments. Here’s how they work:

- Precision Cutting: Thin metal fins are meticulously carved from a solid block at an optimal angle. This creates a dense network of fins that maximize surface area for heat exchange.

- Consistent Performance: The repetitive cutting process ensures uniform fin spacing and structure, leading to reliable and predictable cooling performance.

- Enhanced Efficiency: Compared to stitched fin heat sinks, skived fins offer an 8-15% improvement in cooling capacity, keeping your high-power devices operating optimally.

Ideal for demanding applications:

Skived fin heat sinks are perfect for a wide range of applications requiring superior heat dissipation in air-cooled environments, such as:

- Electronics: Power supplies, servers, and high-performance computing systems.

- Power Conversion: UPS systems, inverters, and motor drives.

- Renewable Energy: Wind power converters and solar inverters.

Products

- Standard Heat Sinks

- Bonded Heat Sinks

- Skived Heat Sinks

- Extrusions

- Downloads

Company

- About Us

- Services

- Contact us

- Inquiry

- Certification