Friction stir welding

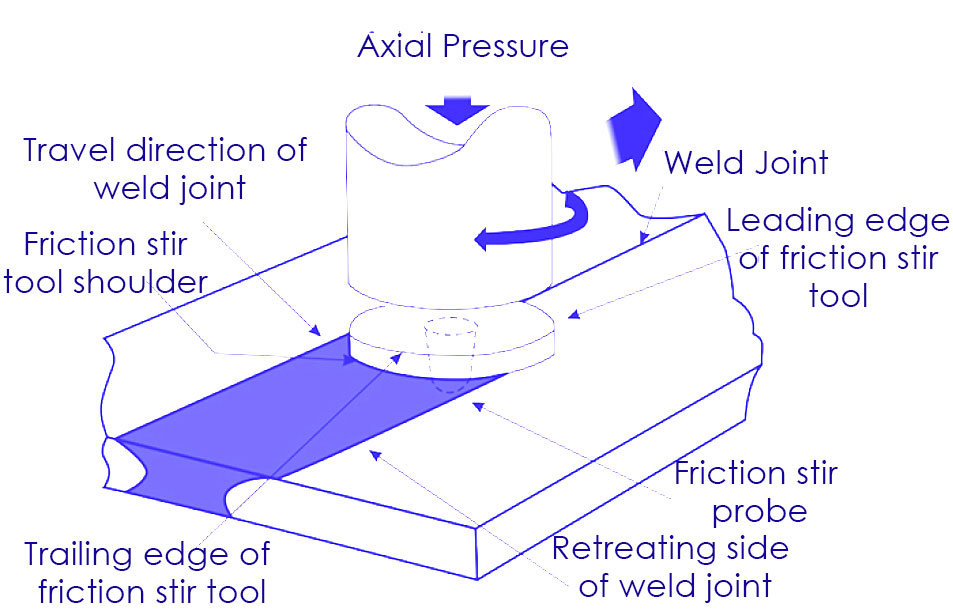

Friction welding is to realize the solid-state welding approach. Under the effect of pressure and with the effects of constant or increase pressure and torque, the relative motion between the welding contacts generates the heat of friction and plastic deformation heat. This effect increases the temperature in the neighboring area to the temperature range which is slightly lower than the melting point. The material’s resistance to deformation is reduced and its plasticity is enhanced. As the oxide film on the interface is ruptured and with the effect of upsetting pressure, the material generates plastic deformation and begins to flow. The molecular diffusion and recrystallization therefore realize the solid-state welding approach.

Friction welding is usually accomplished by the following four steps.

1. Transform mechanical energy into thermal energy. 2. Plastic deformation of the material. 3. The setting pressure under thermoplastic phenomenon. 4. Molecular diffusion and recrystallization

As compared to conventional welding approaches, friction welding’s major difference is to keep the increased temperature due to the energy obtained by the metal to be welded below its melting point. That is, the metal is welded under the solid state which is similar to forging under its thermoplastic state.

As compared to conventional welding, friction welding has the advantages of higher-quality welded connections which meet the requirements of seam strength and base material strength, higher welding efficiency, stable quality, better consistency, and the realization of dissimilar metal welds.

Using friction welding for heat sinks can resolve the technical bottleneck of joining two or more materials to form high-aspect-ratio ultra-wide products. Moreover, its tooling cost is lower with a short cycle time and higher stability. Based on the data that has been accumulated by our R&D team in the long run, Winshare Thermal has developed several standard materials and we keep enhancing the database of our standard materials so as to provide our clients with more joint solutions for selection.

STEP 1: Two or more materials.

STEP 2: Join the materials by friction welding to form a larger cross section.

STEP 3: Form the integrated appearance and uniform performance after machining.

Reference Products

Products

- Standard Heat Sinks

- Bonded Heat Sinks

- Skived Heat Sinks

- Extrusions

- Downloads

Company

- About Us

- Services

- Contact us

- Inquiry

- Certification