Stacked Heat Sink

Stacked heat sinks are formed by using a high pressure to press single fins, multiple fins, and single extrusions together into a stacked heat sink. This type of stacked fin heats which are formed by press-fit approach can realize a cooling structure that has both top and bottom base plates for mounting power devices. No interface material is required for assembly when using this technique and it has the benefits of low development cost, high flexibility in forming heat sinks with different width and structures so that it is highly universal. This technique has been widely used in the cooling of high power devices such as power inverters and transformers, generators, etc.

Stacked heat sinks have advantages such as increasing cooling area while forming a closed passage at the same time so as to achieve higher thermal performance, no restriction on it volume, higher strength, lower manufacturing cost, easier installation and maintenance, longer service life, etc.

Via our technical innovations, Akash Enterprises has mastered the technique of re-stacking aluminum extrusions for the production of high power heat sinks. We have several mature production lines for stacked heat sinks and have acquired the endorsement from Israel’s military enterprises since we manufactured several batches of large stacked fin heat sinks.

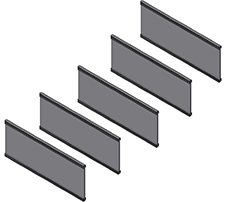

STEP 1: Cut the aluminum extrusions into single pieces of the heat sink according to the design drawings prepared by engineers.

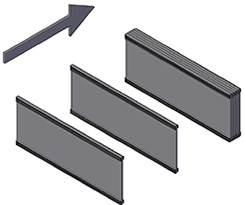

STEP 2: Single pieces of heat sinks are joined together by the stamping technique.

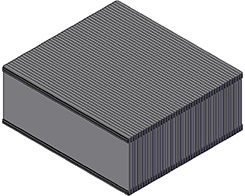

STEP 3: Carry out surface machining such as fly-cuts on the semi-finished products. Further processes such as tapping, drilling, and grooving can be carried out so as to form a finished stacked fin heat sink.

Reference Products

Products

- Standard Heat Sinks

- Bonded Heat Sinks

- Skived Heat Sinks

- Extrusions

- Downloads

Company

- About Us

- Services

- Contact us

- Inquiry

- Certification